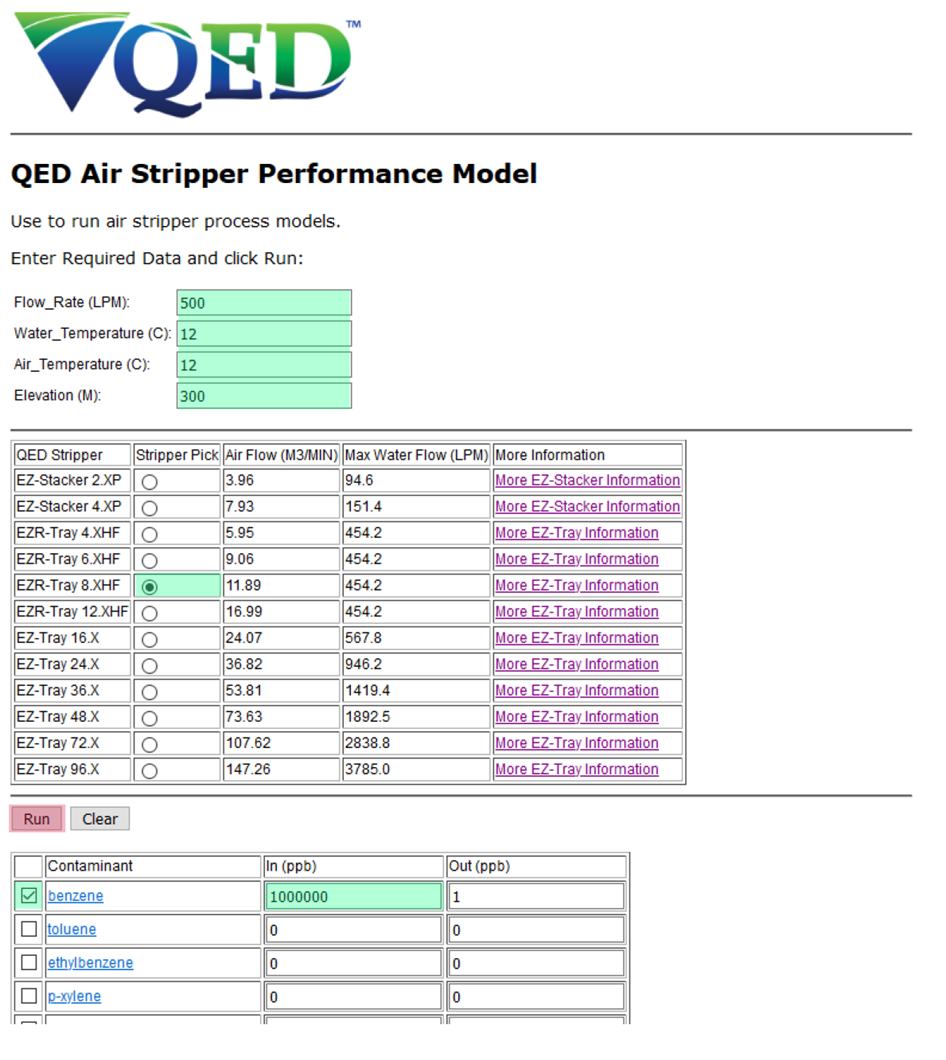

Air Stripper Calculator

Use this calculator to select an air stripper model. It is simple; just follow these steps:

- Enter required fields

- Hit RUN button for results

- Need a contaminant modeled which is not on the list? Email your request to TreatmentGroup [at] QEDEnv [dot] com

Air Stripper Calculator (Imperial Units)

Air Stripper Calculator (Metric Units)

Air Stripper Calculator (Imperial Units)

Air Stripper Calculator (Metric Units)